|

|

Tower Structure

- The CRS slide ways with UHMW bearings allows for smooth operation.

- Flat cable (designed for constant flexing) is used for carriage power while competitors use regular power cord which is prone to shorting due to the constant flexing.

- Dual chain lift drive (similar to a Forklift) is used to ensure smooth,effortless lifting of the carriage. Competitive single chain design causes chatter and uneven motion.

« BACK |

| |

|

|

No-Thread Film Carriage

- Auto-height Photo-eye mounted in carriage for protection.

- CARRIAGE DOOR OPENS FOR EFFORTLESS ROLL CHANGE

Simply open the door, lay the film across and close the door. Its that simple !!!

- Dual Safety Latch ensures door is closed during carriage.

- Lexan Cover is in front of the carriage preventing the operator from putting their hands inside while the rollers are turning.

- Dual Upper & Lower carriage limits.

« BACK |

|

|

Table Drive

- 22 Lube-Free table supports are up to double the amount provided by competitors for similar 4 000 Lbs load capacity.

- The table supports are Urethane coated for quiet operation.

- Cross braced structural steel is welded to reinforce the base for proper function on uneven floors.

- Direct chain drive ensures positive rotation compared to belt slippage and friction wear found with competitive drive systems.

« BACK |

|

|

AC Motor Controls / Variable Frequency Drives (VFD)

- No maintenance required compared to DC Motors and drives used by the competition.

- Provide unlimited control of speeds, accel, and decel along with starting power compared with throw-away DC boards.

- Totally enclosed drives provides unrivaled safety compared to the hazardous DC boards used by the competition.

- Alarm diagnostics enable simple troubleshooting.

- Exact digital adjustments compared to guesswork with thumbwheels on competitive DC Boards.

- Internal surge protection protects against blowing the board (very common in DC boards).

« BACK |

|

|

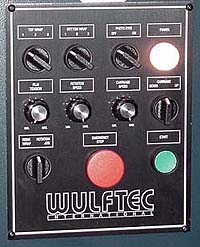

Control Panel

WLP-150

- NEMA 4 (Water Tight) enclosure.

- NEMA 4 X (corrosion proof) selector switches.

- Safety Push/pull E-Stop.

- Complete jog & speed adjustment controls.

- Photoeye on/off selector.

- Start push button.

- Separate Top & Bottom wrap counters.

- Reinforce wrap button applies more film anytime during the wrap cycle when extra film is needed.

« BACK |

|

|

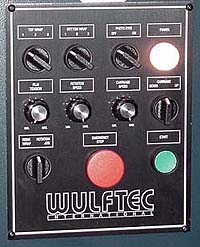

Control Panel

WLP-200

- NEMA 4 X (corrosion proof) selector switches.

- Push/Pull Safety E-Stop.

- Reinforce wrap allows extra wrap to be applied at the same location on the load.

- Separate up /down Carriage speed adjustment improves film savings.

- Separate 0-9 top & bottom wrap selection.

- Adjustable film tension control.

- Auto height Photo-eye on/off selector.

- Cycle Pause Capability.

- Spiral Up, Spiral Up/Down and top cover pause cycle selection.

« BACK |